Reverse engineering as a structural solution to EGR problems

After Dieselgate, numerous 1.6 TDI and 2.0 TDI engines are struggling with persistent EGR problems. But why? And how does Auto Elect offer a lasting solution thanks to reverse engineering?

Since the Dieselgate scandal, the EGR valve - the part that directs exhaust gases back into the engine to reduce NOx emissions - a source of frustration for many car owners and workshops. What was once intended to make engines cleaner has, in practice, turned out to primarily result in expensive repairs, downtime and dissatisfied customers. At Auto Elect, therefore, we have taken a structural approach: reverse engineering. Thus, we do not just supply a replacement part, but a technically improved solution.

What went wrong after Dieselgate?

To understand why so many EGR systems fail, we need to go back to Dieselgate for a moment. VAG group engines, such as the EA189, were equipped with software that recognized when the car was on the test bench. During such a test, the EGR system worked at its maximum to reduce NOx emissions. But during normal driving, the system was largely turned off. This resulted in smoother performance and less pollution in the EGR system itself.

Upon discovery of this practice, governments required the manufacturer to perform a software update. As a result, the EGR valve now had to remain active at all times. Good for emissions figures according to the standard, but the original system was not designed for this. The result: excessive pollution, stuck valves, faulty engines and frequently recurring malfunctions.

The problem with the original design

The original EGR system was already prone to fouling, especially in combination with aging particulate filter. The software update required the system to run permanently, increasing the load tremendously. As a result, EGR valves clogged or failed more quickly. And because the exact same original parts were often fitted, the problem kept recurring.

Workshops and customers were powerless: replacements sometimes helped briefly, but did not provide a structural solution. To everyone's frustration.

What does Auto Elect do differently? Reverse engineering.

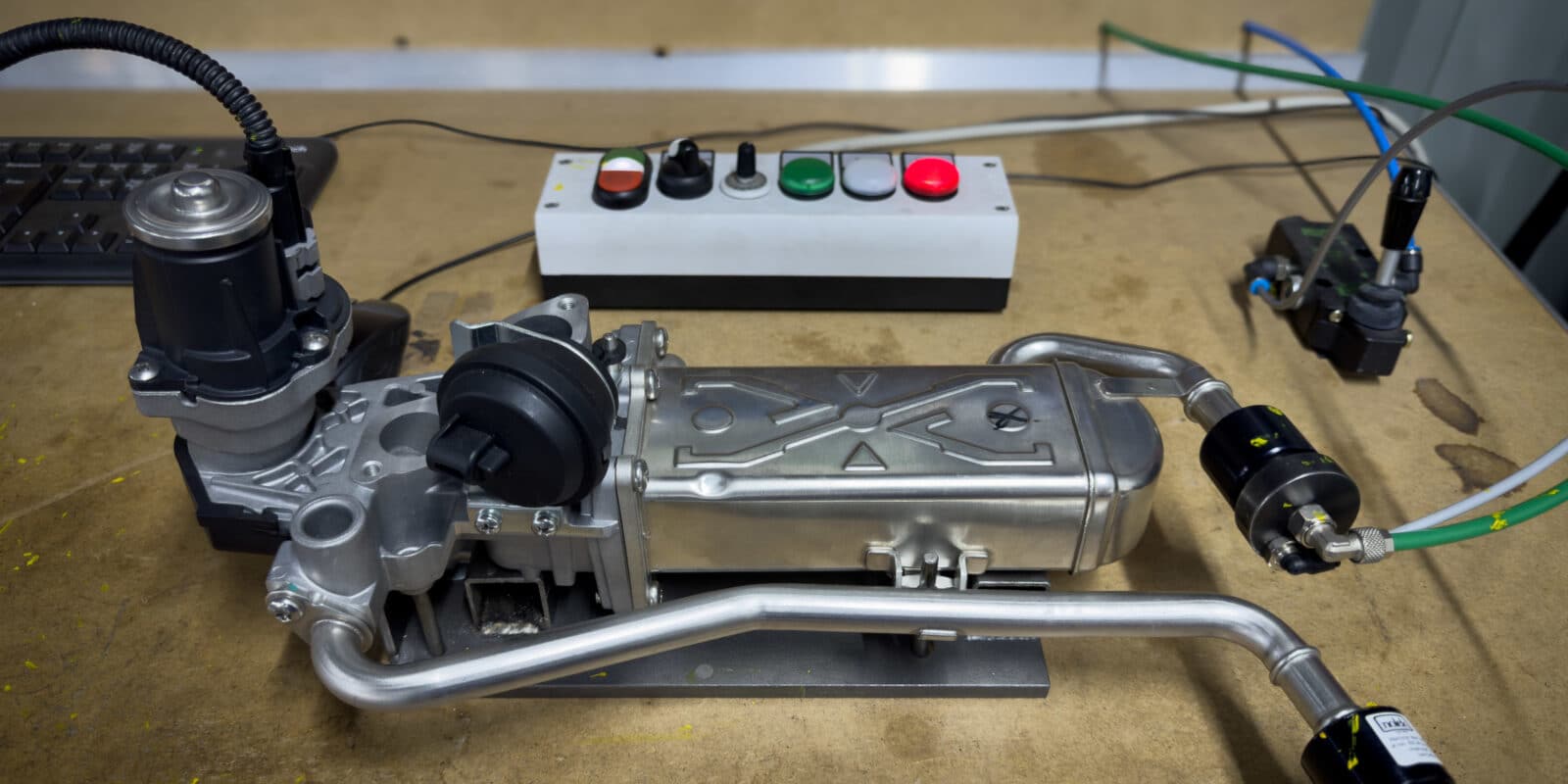

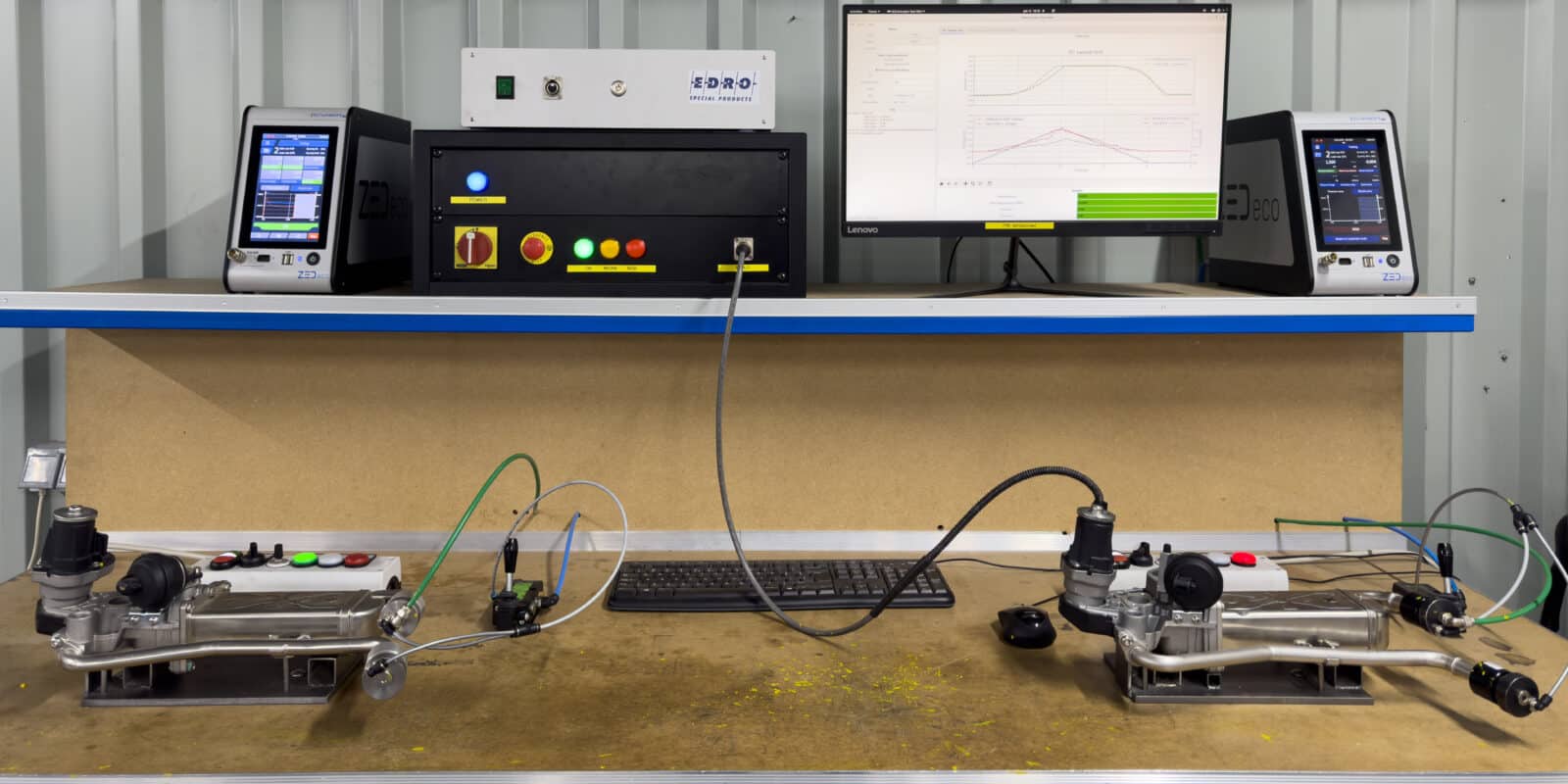

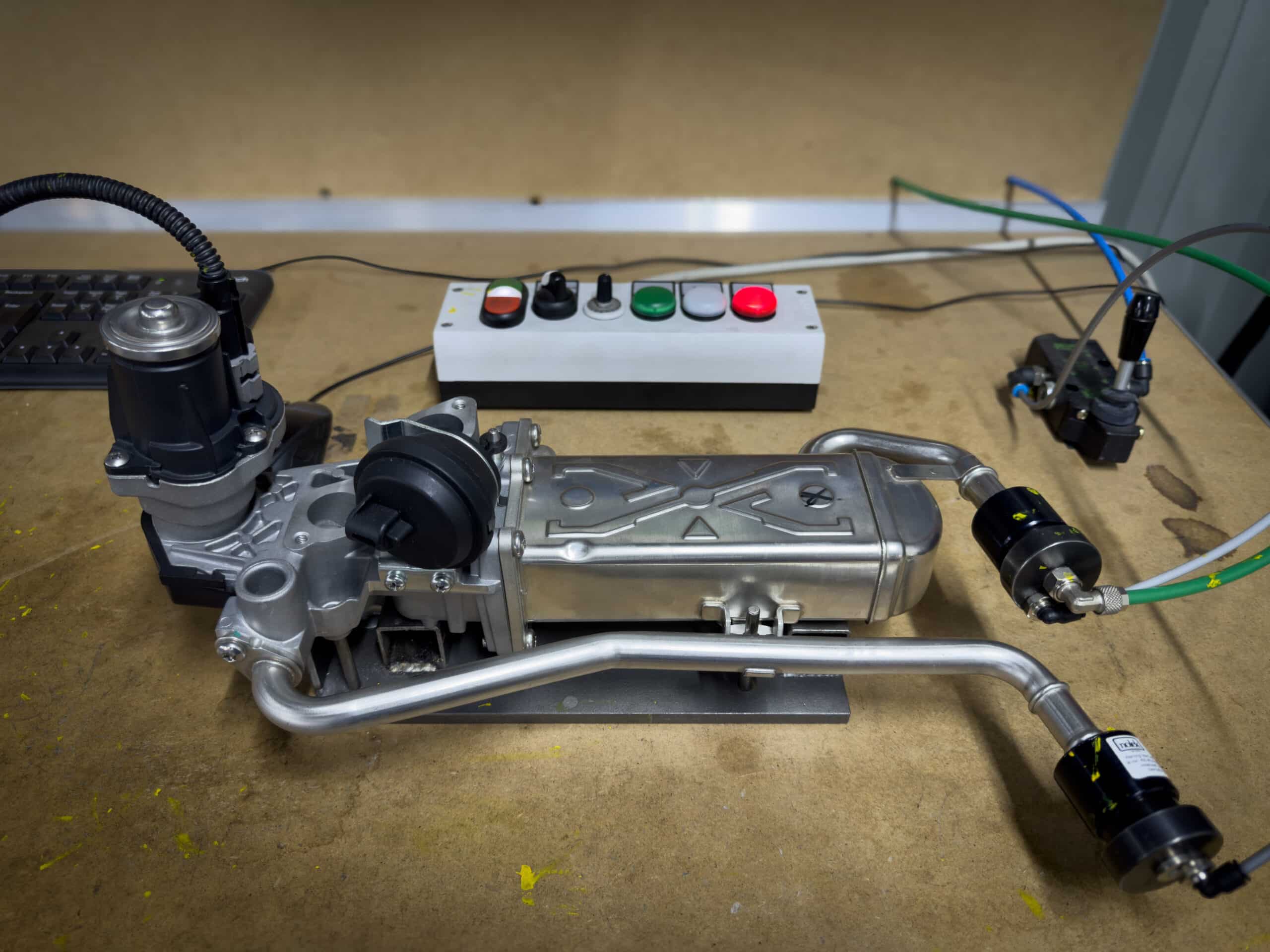

At Auto Elect we analyze not only what breaks down, but more importantly why. Based on reverse engineering, we identified and addressed the weaknesses of the original design of the VAG EA189 engines. This resulted in a modified EGR module within our Gaured program, specifically suited for the higher load after the software update.

Key improvements:

- Better materials: For all wear-sensitive and heat-loaded parts, significantly extending service life.

- Modified cooler: Better heat transfer and less chance of internal leaks.

- Custom gasket: More durable and resistant to high temperatures.

- Valve mechanism optimization: Less susceptible to contamination and overloading.

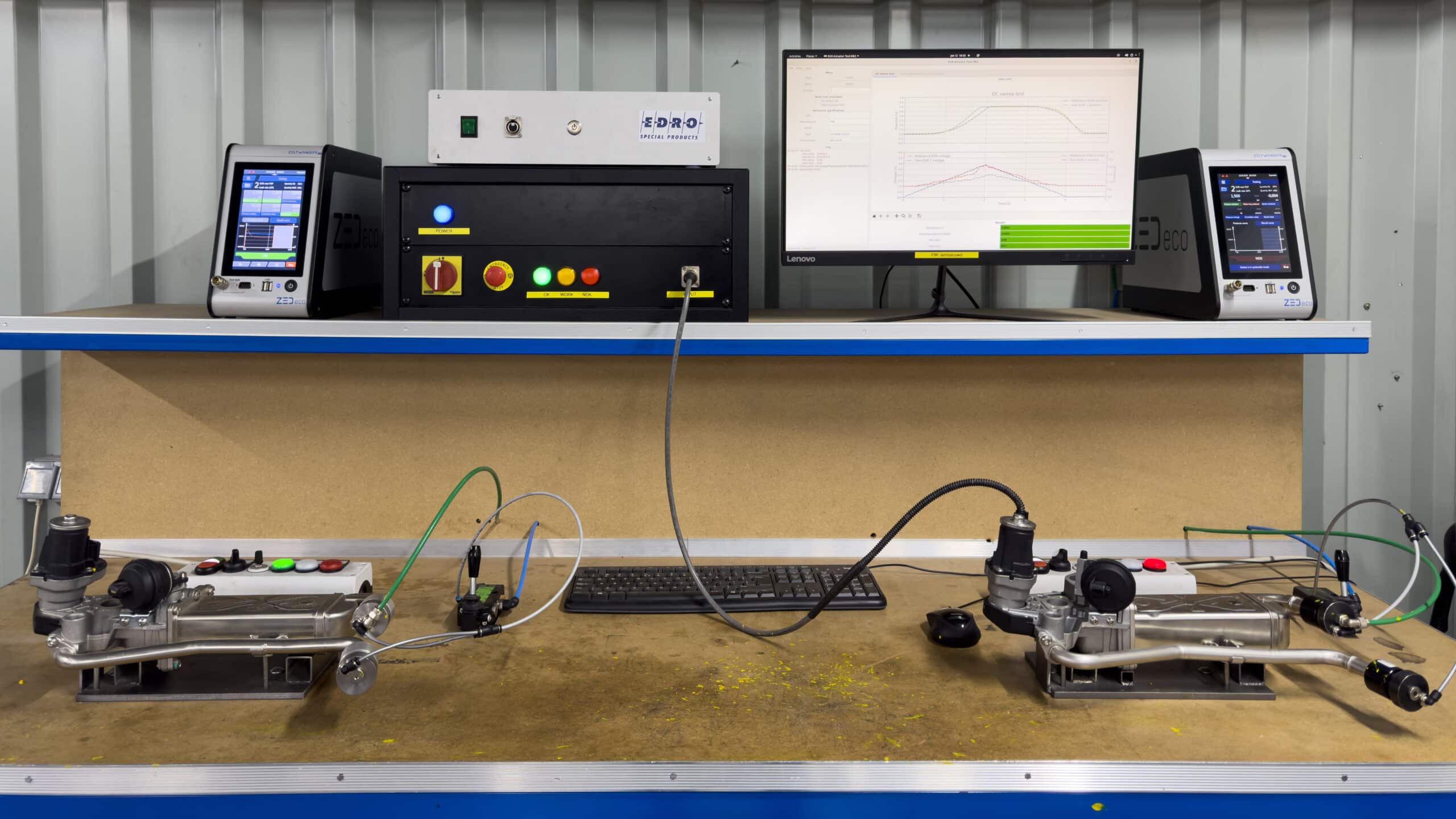

In addition, these modules are rigorously tested, both during production and extra in the Netherlands. They are checked for cooling water leakage with certified equipment as well as the correct operation of the valve and position sensor.

Correct assembly remains crucial

A better EGR solution starts with better design, but proper assembly and diagnosis are just as important:

- Preferably, do not disassemble the cooler from the valve body; the original gasket is for one-time use and replacing it often causes problems.

- Always check the exhaust manifold and supply pipes for leaks; hot leak gases can cause new damage.

- Watch for other causes of cooling water leakage, such as a faulty oil cooler.

- Contamination in the EGR valve is often a result of a clogged or malfunctioning particulate filter - fix the cause as well.

Following these steps will keep the system functioning sustainably.

Structural difference for customer and environment

With reverse engineered EGR modules from Auto Elect, we offer garages and their customers more than just a replacement part. Our solution prevents recurring failures, shortens downtime and reduces maintenance costs. And because EGR function is retained, NOx emissions are also reduced. That's better for the car, better for the customer and better for the environment.

Simply turning off the EGR valve sometimes seems like a quick fix, but it is not allowed, bad for the environment and often disastrous for other components.

Conclusion

The EGR problems after Dieselgate are a clear example of how regulations, engineering and practical use can clash. By reverse engineering, we at Auto Elect don't just deliver a new part, but a structurally better solution that really works in practice. This is how we help garages and motorists move forward - sustainably, reliably and responsibly.