The importance of quality control in remanufactured parts

In the world of automotive remanufacturing, restoring used parts is a valuable way to combine sustainability and cost savings. But the real key to success is not just in the remanufacturing itself - it's in the quality of control afterwards.

At Auto Elect, we know: revision without thorough quality control is a gamble. A remanufactured part must not only function, but that do as reliably, safely and efficiently as a new part. That's why we have developed an inspection process that goes beyond the standard. In this blog, you will read why quality control is essential with remanufactured parts, and how we master this process to perfection.

What are remanufactured parts?

Remanufactured parts are used vehicle parts that are disassembled, cleaned, repaired or replaced where necessary, and reassembled into a product that is technically equivalent to a new part. Consider parts such as wheelhouses, turbos, shock absorbers and master cylinders.

Overhaul contributes to circularity, saves money and lowers the carbon footprint. But all of this hinges on one factor: quality. And you don't secure those without a careful monitoring process.

1. Safety always comes first

Components such as steering boxes, turbos, shock absorbers and master cylinders play a vital role in vehicle steering, propulsion and braking. If a remanufactured component has not been thoroughly tested, it can fail along the way - resulting in potentially dangerous situations.

At Auto Elect, we therefore carry multiple quality checks out, including functional tests and visual inspections. Every part we deliver is individually tested and assessed for reliability. No sampling, just 100% verification.

2. Increase reliability and longevity

A remanufactured part must not only function well today, but still do so in 10,000 or 100,000 kilometers. We replace wear-sensitive parts preventively, even if they could "just barely" work. Our quality checks ensure that early failures are minimized, resulting in longer life and satisfied customers.

3. Performance to factory standards.

Whether it's the pressurization of a turbocharger, the damping of a shock absorber or the precision of a steering box - performance must be right. Customers expect a remanufactured part to perform like the original. That's why at Auto Elect perform performance tests that directly match the manufacturer's original specifications. Thus, we do not supply just any part, but a product that meets all technical expectations.

4. Lower overall cost for the customer

If a remanufactured part has not been properly tested, there is a chance that it will fail again within a short period of time. The cost? Reassembly, re-replacement, and maybe even consequential damage to other systems. Thanks to our comprehensive quality checks, you avoid those risks. You save not only on the part, but also on labor hours and frustration.

5. Compatibility with modern vehicle electronics

In modern vehicles, every component is part of a complex electronic network. If a remanufactured component - for example, an electrically controlled steering box or a variable geometry turbocharger (VGT) - does not communicate correctly with the engine management or other modules, it leads to error messages or malfunctions.

That's why at Auto Elect we also carry compatibility checks out. We simulate vehicle conditions and check whether the component "talks" to the on-board computer without problems. This prevents surprises during installation.

6. Support with installation instructions

We understand that the installation of technical or electronic components can create real-world challenges. That's why Auto Elect develops - where necessary - specific installation instructions to provide optimal support to our customers. This is particularly important with electronic products, where incorrect assembly can lead to communication problems with the vehicle or damage to sensitive components. With clear, practice-oriented manuals, we minimize the risk of assembly errors and significantly increase first-assembly success.

7. Compliance with industry standards and traceability.

Our working method is based on professional standards and procedures that we continue to improve continuously. Each remanufactured part is given a unique identification. In this way we ensure full traceability and compliance with ISO-worthy quality criteria - transparency that you as a customer can rely on.

8. Sustainable, but without concessions

Remanufacturing is good for the environment, but only if it is done right. We do not believe in reuse for reuse's sake, but in sustainable reuse with quality guarantee. Only parts that pass full quality control go back on the road. The rest are disposed of responsibly or used as donors. No waste, but certainty.

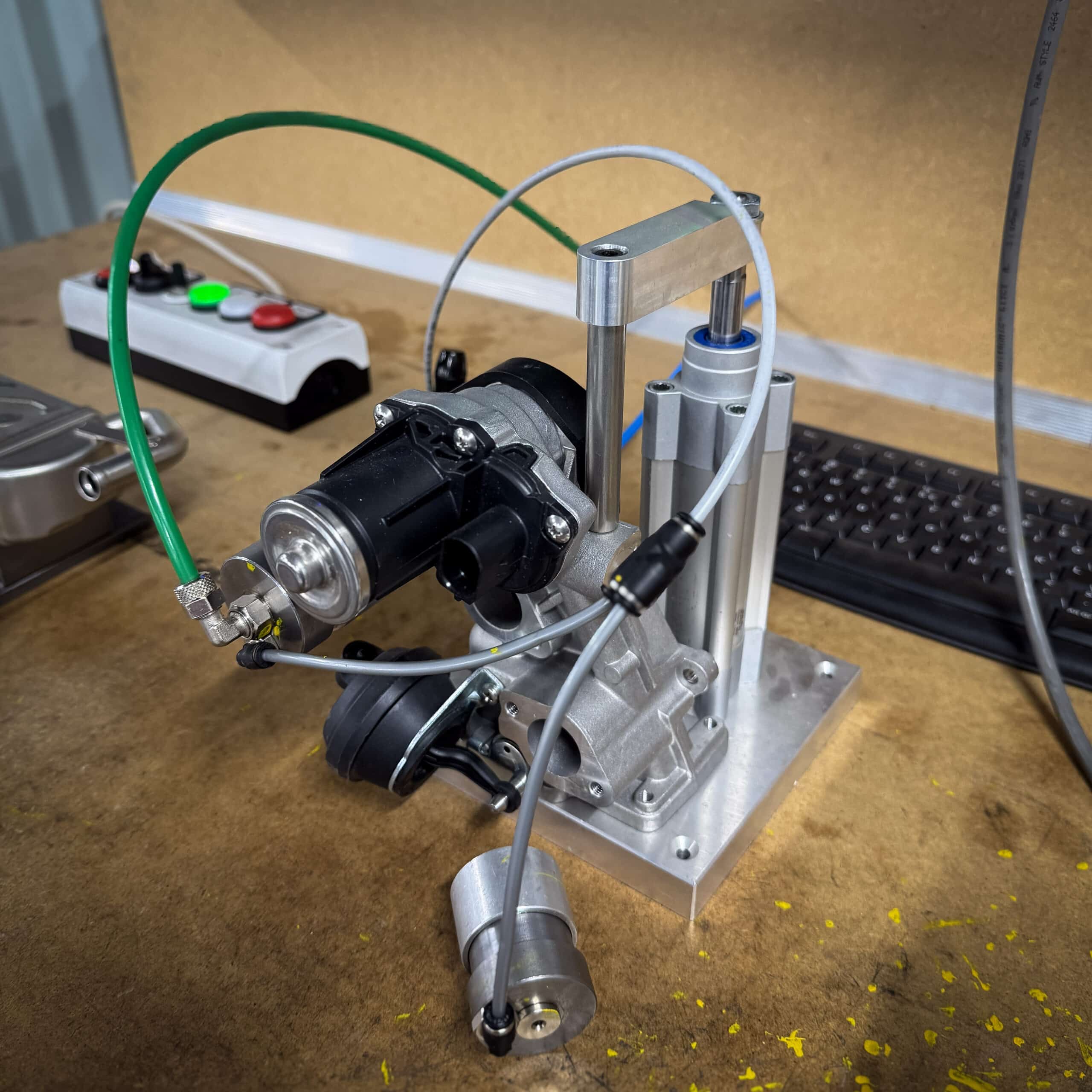

Our method in practice

At Auto Elect, we use a multi-step quality control plan for remanufactured parts such as steering boxes, turbos, shock absorbers and master cylinders:

- Visual inspection: Detection of wear, hairline cracks, damage or assembly errors.

- Functional test: Check that the component is functioning properly under load.

- Electronic compatibility test: For parts with software or sensors: does it work seamlessly with modern vehicle systems?

- Performance Test: Measuring whether the part delivers the performance specified by the manufacturer.

- Final inspection & documentation: Each part is uniquely labeled with traceable test reports.

Why choose Auto Elect?

At Auto Elect, you get more than a remanufactured part. You get control, assurance and quality. Whether it's a turbocharger, a shock absorber, a master cylinder or an electric steering box, we make sure it works as it should - and often even better.

Curious about how we work or our current inventory? Please contact us and discover how we take quality to the next level.